Aluminum Powder Manufacturing

About this Project

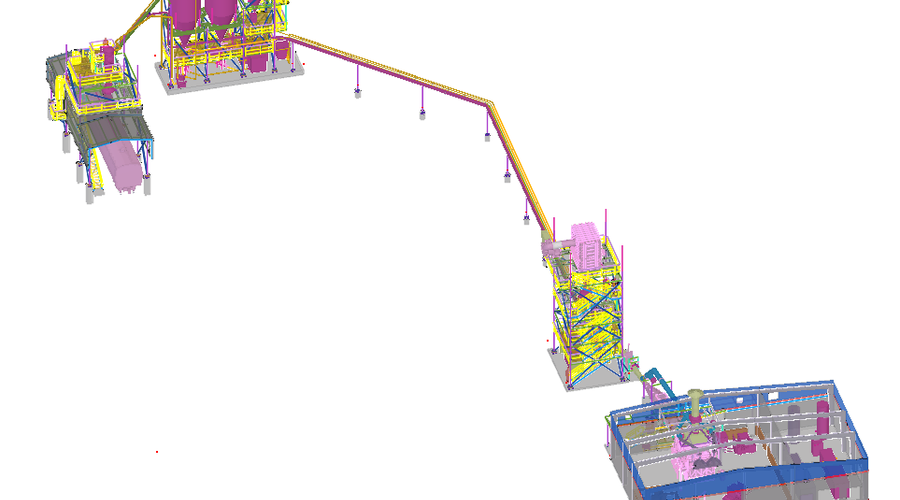

The scope of this project was the installation of a new powder manufacturing line at an existing facility. This includes a new furnace, atomizer, classifiers, storage silos, and truck or rail loadout system. LVTA served as the lead consultant, coordinating with the electrical engineer, site engineer, geotechnical engineer, equipment suppliers, and the contractors. In addition to providing civil and structural engineering, LVTA provided mechanical chute, pipe, and duct design, and developed new prototypes to improve the reliability, efficiency, and functionality of the liquid metal handling system. LVTA also consulted with the owner to aid in bid specification preparation and bid evaluation to expedite and organize supplier and contractor selection process. Key challenges in this project include the following:

- Design for explosion abatement and safety;

- Challenging subsurface conditions, including a very high water table;

- Coordinating between two primary equipment suppliers that were each responsible for guarantying a portion of the process, and ensuring proper and clear division of responsibility;

- Limited historical record-keeping;

Project Gallery