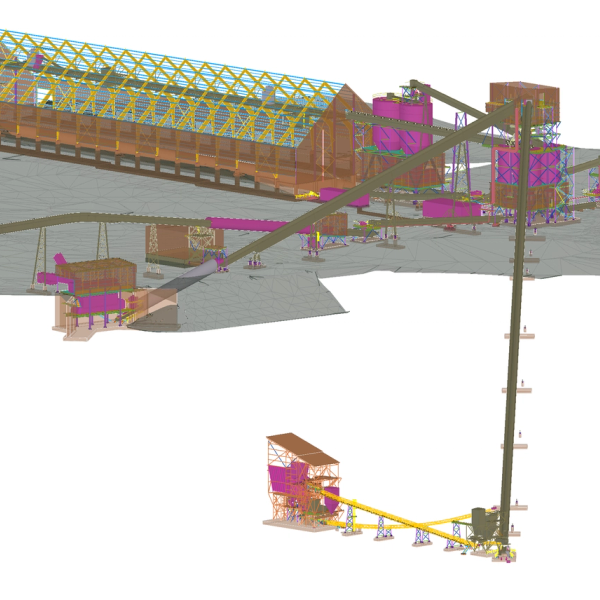

Cement Raw Mill Feed System

About this Project

The scope of this project was the raw mill feed system for a cement plant modernization for a new kiln line designed by others. Included in the scope was the relocation of a primary crushing system from another site, a new limestone linear storage hall (PEMB) with reclaim system, a new additives unloading system, two new additives storage bin structures, and a raw mill feed conveyor with cross belt analyzer. The relocated primary crusher system included a screen and recirculation conveyor and was to be located at the base of the quarry. An included belt conveyor elevated the crushed limestone out of the quarry, then onto a horizontal tripper conveyor that fed the storage hall. The additives unloading system was a covered building positioned near the highwall of the quarry to take advantage of the natural grade change with a bottom dump grizzly in the floor. Below the grizzly was a feeder feeding a conveyor that elevated the material to the top of the additives bin structure. The additives were then metered onto the storage hall reclaim belt and were conveyed to the raw mill. LVTA’s responsibilities included layout of the system, mechanical arrangement, chute design, dust collection design, coordinating with equipment vendors, and design of the structures and foundations to support the process. Key challenges in this project include the following:

- Retrofit of the relocated primary screening to accommodate the new site and also to correct known vibration issues

- Coordinating with a variety of equipment vendors

- Designing a foundation for an additives dump station positioned on the edge of the quarry face

Project Gallery