Petroleum Products Mixing and Packaging

About this Project

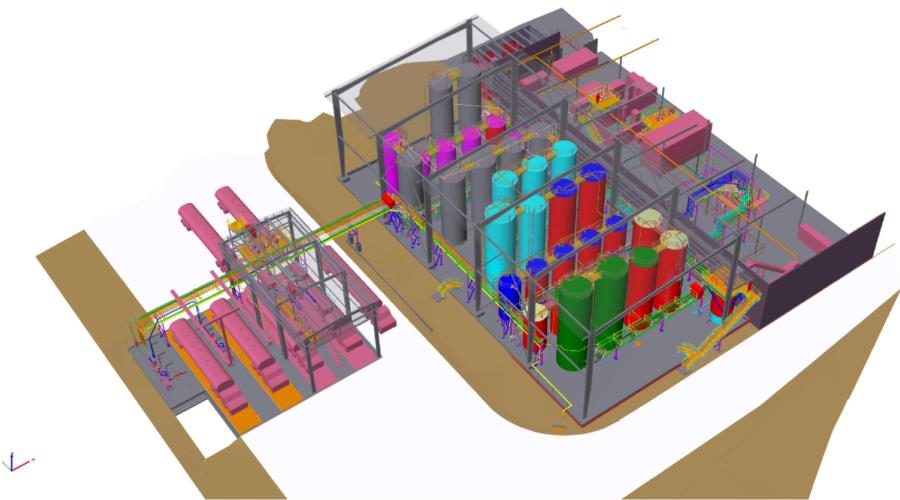

The scope of this project was to design and layout a new bulk liquid unloading system, new tank farm, new blending and dying equipment, new bulk loading system, and new packaging equipment on a small existing site with an existing warehouse building. The unloading system included two covered truck unloading lanes and provisions for a future rail unloading station. The tank farm included 41 tanks to store 41 different raw and finished goods and provisions for four future tanks in a secondary containment area under roof cover. The blending, dying, and packaging equipment was located Inside the existing building, along with finished goods and other raw and intermediate goods storage. Other portions of the scope include a new compressed air system, new fire water and fire chemical system, new oil-water separation system, and mechanical design for a new viscosity modification shredder and feeder. Key challenges in this project include the following:

- Capturing, containing, and treating all potentially contaminated rainwater at a site with an extremely high design rain intensity

- Extensive fire protection requirements

- Over Three miles of piping in a condensed footprint

Project Gallery