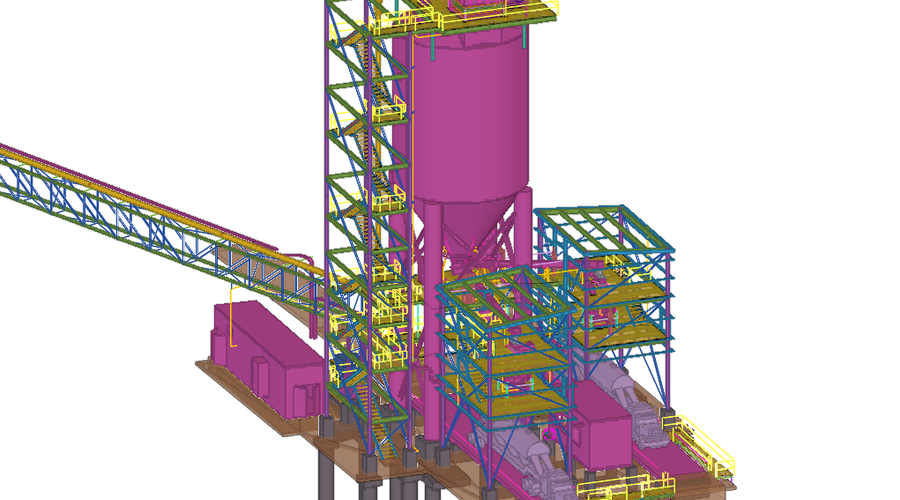

Truck Loadout Silo

About this Project

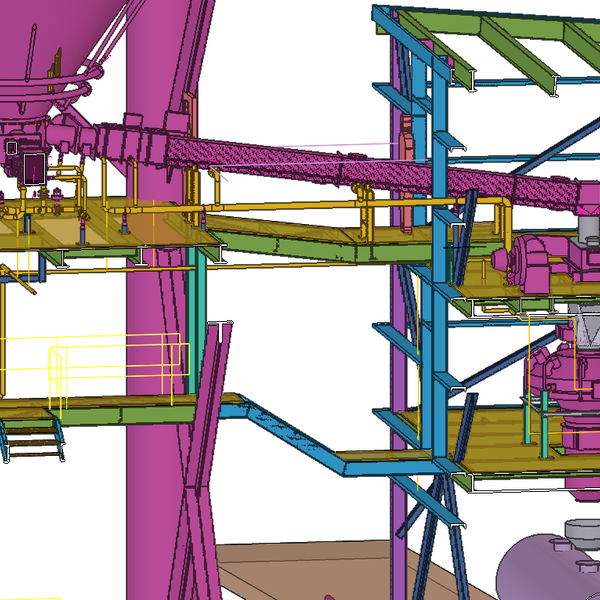

The scope of this project was to increase the plant’s capacity to load trucks by installing a new storage silo and two bulk loading stations located approximately 800 feet from the existing storage and loading operations. LVTA was responsible for developing the overall site plan regarding traffic flow, specifying the conveying system to transport material from the existing storage silos to the new silo, and the layout of the new truck loading stations. The transport system that feeds the new silo consists of a pneumatic pump that accepts material from three existing silos through a series of aerated bin bottoms and air gravity conveyors. The bulk loading systems consist of flow control gates, air gravity conveyors, and loading spouts with integral dust collection. Key challenges in this project include the following:

- Providing an equipment layout that would work within the limited space beneath the three existing cement silos while minimizing the size of the aerated bin bottoms required;

- Design of support structures for the conveying line that transports material to the new silo;

- Design of large diameter bin bottoms capable of accommodating the large material loads from the silo with modularized pieces that allowed installation within the confines of the existing space.

Project Gallery